Key Features

Landing Pad

Amagi Vertiports, Plans on using Skyports innovative vertipad that mitigating downwash and outwash issues.

Specifications:

Size:

50x50 feet (2,500 sq ft), suitable for Joby eVTOLs.

Material:

Reinforced concrete (6 inches thick, ASTM C150 Type I cement, No. 5 rebar at 12-inch spacing), designed for 10,000 pounds (dynamic load for takeoffs/landings).

Markings:

Yellow “H” (FAA standard for heliports/vertiports), painted with reflective epoxy paint.

Drainage:

1% slope (0.5 inches over 50 feet) to direct runoff to a perimeter drainage system.

Operational Role:

Single pad for all takeoffs and landings. With 40 daily takeoffs/landings (20 round-trips),

Charging and Boarding

Charging Stations (3 Units)

Specifications:

Size:

20x20 feet each (1,200 sq ft total for 3 units), accommodating Joby eVTOLs.

Material:

Reinforced concrete (6 inches thick, 10,000-pound capacity), with retractable canopies (steel frame, polycarbonate roof) for weather protection.

Charging:

100 kW DC fast charger per station (CCS2 connectors), supporting simultaneous charging of 3 eVTOLs. Total power draw: 300 kW.

Operational Role:

eVTOLs taxi to charging stations after landing. Each charge takes ~30 minutes (Joby’s battery capacity ~40 kWh, 80% charge in 30 minutes at 100 kW). With 20 round-trips, each eVTOL needs ~2 charges/day (40 charges total). Three stations handle this load, with each station charging 13-14 eVTOLs/day.

Boarding Stalls (5 Units)

Specifications:

Size:

20x10 feet each (1,000 sq ft total for 5 stalls), designed for passenger boarding/deboarding.

Material:

Concrete platform (4 inches thick, 5,000-pound capacity), with a 5-foot-wide canopy (steel frame, polycarbonate) for shade.

Access:

Connected to the terminal via a 50-foot pedestrian pathway (5 feet wide, concrete).

Operational Role:

eVTOLs taxi to boarding stalls after landing or charging for passenger deboarding/boarding. Eachstall handles 8 passengers/day (40 passengers / 5 stalls), with a 5-minute turnaround per eVTOL (boarding/deboarding 2 passengers). Stalls are adjacent to the terminal for quick passenger access.

Terminal and Drone Delivery

Terminal

Specifications:

Size:

1,500 sq ft (reduced from 2,000 sq ft to fit compact design), glass-and-steel structure with a flat roof.

Components:

- Check-in: 2 counters (10x5 feet each).

- Security: 20x10 feet (metal detector, X-ray machine).

- Lounge: 400 sq ft (seating for 15 passengers).

- Waiting area: 800 sq ft (glass walls for visibility).

Structural Integrity:

Steel frame with columns every 20 feet, designed for wind loads (90 mph, Washington State building code) and seismic Zone D.

Roof:

10 kW solar panels (50 panels, 10x2 feet each, 500 sq ft), supported by steel beams.

Operational Role:

Processes 40 passengers/day, with a 10-minute dwell time per passenger (check-in, security, lounge). The terminal supports this throughput, with capacity for future growth (up to 80 passengers/day).

Drone Delivery Systems

Launch/Recovery Zones:

Zipline Zone:

40x20 feet (800 sq ft), with a Zip launch catapult (10x5 feet) and recovery system (10x10 feet). Surface: Reinforced concrete (4 inches thick, 5,000-pound capacity).

Amazon Zone:

30x15 feet (450 sq ft), for VTOL operations with a marked drop zone (10x10 feet) for parachute deliveries. Surface: Same as Zipline.

Markings:

Yellow “D” markings with directional arrows.

Drone Storage Area:

Size:

800 sq ft (40x20 feet)

Loading Bay:

10x10 feet for ground staff to transfer packages.

Operational Role:

Stores packages for 100 daily flights, with staff loading/unloading during operations.

Battery Swapping Stations:

Size:

Two 10x10-foot stations (200 sq ft total), one for Zipline, one for Amazon.

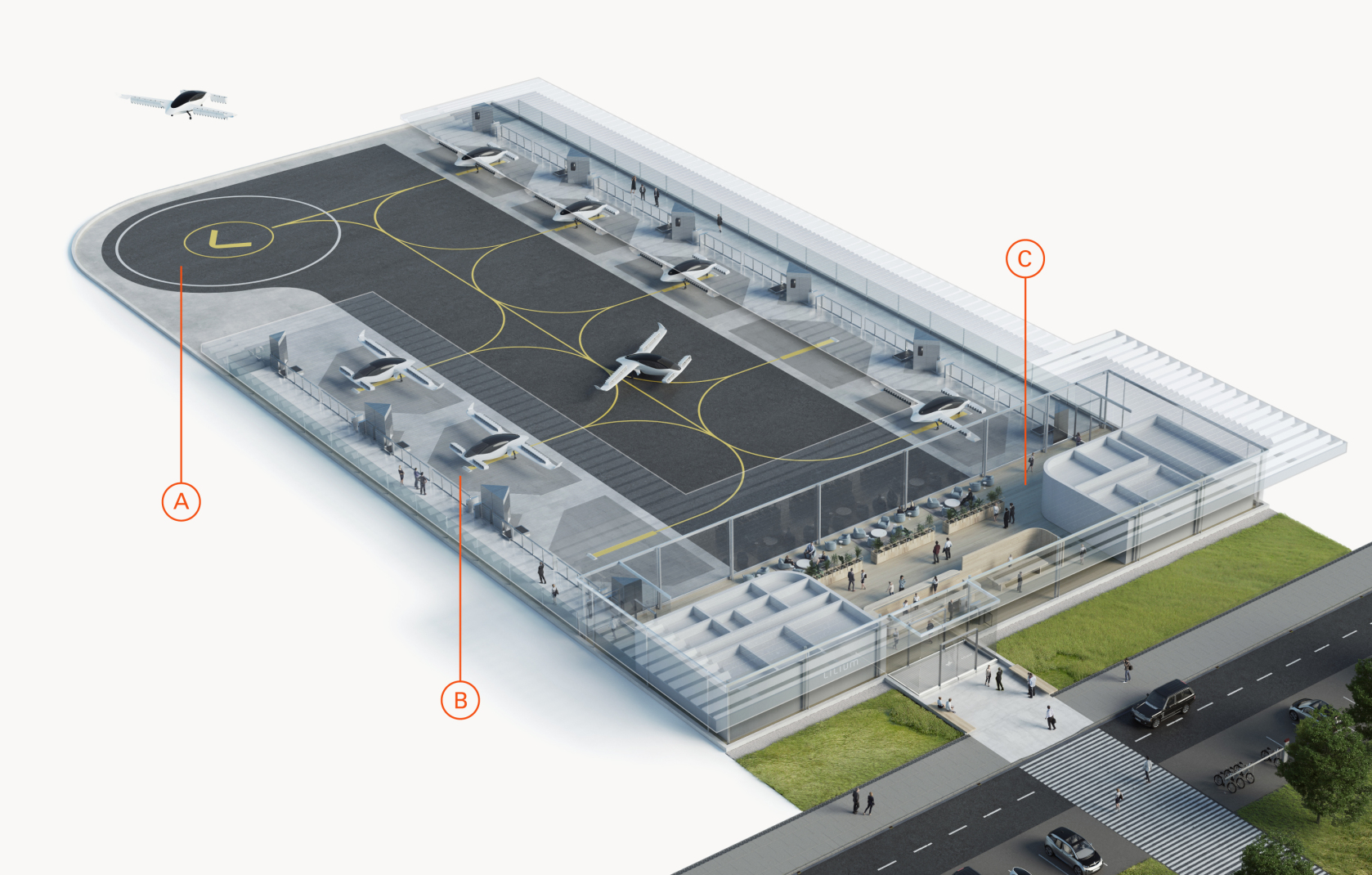

Modular Vertiport Design

Updated Vertiport Design Overview

The new design includes:

(A) Landing Pad**: For eVTOL takeoffs and landings.

(B) Charging Stations**: For eVTOL charging and parking.

(C) Terminal**: For passenger processing (check-in, security, lounge).

(D) Boarding Stalls**: For passenger boarding/deboarding.

(E) Drone Delivery Systems**: Launch/recovery zones and storage for Zipline and Amazon Prime Air.

This modular design, developed with Lilium’s expertise, reduces construction time by 30% and scales to meet future demand, with plans to expand to 11 airports across Washington State by 2030, including Friday Harbor, Orcas Island, and Sekiu.